#lpg vaporizer

Explore tagged Tumblr posts

Text

Anil Engineering: Experts in LPG Safety Valves & Storage Tanks

Anil Products: Trusted LPG vaporizer manufacturer delivering top-quality vaporizers and dependable solutions tailored to your business LPG system needs.

visit us at: https://anil-engineering.com/

#LPG Storage tanks#Cryogenic Tanks#lpg vaporizer#excess flow check valve#dry electric vaporizers#lpg vaporizer manufacturers#lpg safety valv

0 notes

Text

Trusted Anil-Engineering lpg vaporizer manufacturers in India

Anil & Company offers the best dry electric vaporizers, providing high-quality products for a smooth vaping experience. Discover top-notch vaporizers at competitive prices.

#LPG Storage tanks#Cryogenic Tanks#lpg vaporizer#excess flow check valve#dry electric vaporizers#lpg vaporizer manufacturers#lpg safety valv

0 notes

Text

The Role of LPG Vaporizers in Efficient Energy Supply

In industries that rely on liquefied petroleum gas (LPG), an LPG vaporizer is a crucial device that enhances the efficiency of gas supply systems. By converting liquid LPG into vapor, these vaporizers ensure a steady and reliable gas flow to meet the demands of industrial, commercial, and even residential applications. Let’s explore how LPG vaporizers work and why they are essential for large-scale LPG users.

What is an LPG Vaporizer? An LPG vaporizer is a device designed to convert liquid LPG into vapor. While LPG is typically stored in liquid form under pressure, many applications require it in a gaseous state. The vaporizer heats the liquid LPG to the point where it transitions into gas, making it suitable for use in gas burners, engines, and other equipment.

How Does an LPG Vaporizer Work? LPG vaporizers work by using either external heat or internal heating elements to facilitate the evaporation process. There are two main types of vaporizers:

-Direct-fired vaporizers: These use a flame to heat the liquid LPG, turning it into vapor. -Water-bath vaporizers: These use heated water to indirectly transfer heat to the liquid LPG.

Importance of LPG Vaporizers in Industry LPG vaporizers play a vital role in ensuring a steady gas supply, especially in situations where the natural vaporization rate of LPG in the cylinder or tank is insufficient to meet demand. This is particularly important in industries that consume large volumes of LPG for processes like heating, drying, or powering generators. Without an LPG vaporizer, the system may experience gas shortages or fluctuating pressures, leading to inefficient operation.

Conclusion For industries that rely heavily on LPG, an LPG vaporizer is an indispensable tool for maintaining efficiency and ensuring a consistent supply of gas. By converting liquid LPG into vapor, vaporizers play a critical role in the smooth operation of gas-powered systems, ensuring that the energy supply is both reliable and safe.

View More: https://www.shreemgaz.in/

0 notes

Text

#lpg vaporizer market size#lpg vaporizer market growth#lpg vaporizer market report#lpg vaporizer market forecast#lpg vaporizer market analysis#lpg vaporizer market outlook#lpg vaporizer market overview#lpg vaporizer market trends#lpg vaporizer market insights#lpg vaporizer market#lpg vaporizer market demand

0 notes

Text

LPG Filling Equipments | LPG Pumps, Vaporisers, Safety Fittings, Trasnfer Compressors

Deneb Solutiosn provides all types of LPG Equipments like, LPG Carousel, LPG Ambient Air Vapouriser, Gas Detecters, LPG Saftey Valves, LPG Safety Fittings & Unloading Arms.

DenEB is an engineering company offering various consultancy and projects services for LPG, Liquefied/Natural Gas, Cryogenic and other related gas facilities. Our team of engineers and consultants bring passion and energy to every project with an approach different from our competitors. Our lasting partnerships with our clients is an advantage and helps sail tough challenges resulting in safe, creative and innovative solutions.

#LPG Filling Carousel Supplier in India#LPG transfer compressors supplier in India#Duplex LPG pump supplier#Simplex LPG pump supplier in India#LPG Ambient Air Vaporizer supplier#LPG Safety Valves Supplier in India

0 notes

Text

Innovative Solutions for Sustainable Gas Purification: Biogas in Kerala

In the lush and resource-rich state of Kerala, the demand for sustainable energy solutions is on the rise. Among these, biogas has emerged as a frontrunner, offering a renewable, eco-friendly alternative to conventional fossil fuels. However, the journey from raw biogas to a purified, usable fuel requires innovative gas purification solutions. Let’s delve into how biogas in Kerala is paving the way for sustainable energy through advanced purification techniques.

Why Purification Matters in Biogas Production

Raw biogas is primarily composed of methane (CH4) and carbon dioxide (CO2), with traces of hydrogen sulfide (H2S), water vapor, and other impurities. To utilize biogas efficiently, especially as a substitute for LPG or in power generation, it must be purified. Purification removes contaminants, enhances methane concentration, and ensures the gas meets quality standards for safe and efficient use.

Challenges in Biogas Purification

High Operational Costs: Traditional purification methods like water scrubbing and chemical absorption can be expensive and resource-intensive.

Environmental Concerns: Inefficient systems often release harmful byproducts, negating the environmental benefits of biogas.

Scalability Issues: Many existing solutions are not suitable for small-scale biogas plants, which are prevalent in Kerala’s rural and semi-urban areas.

Innovative Purification Techniques Gaining Ground in Kerala

1. Membrane Separation Technology

Membrane-based systems are gaining popularity for their ability to efficiently separate methane from impurities. These systems are compact, scalable, and energy-efficient, making them ideal for Kerala’s decentralized biogas units.

Benefits:

High methane recovery rate.

Minimal environmental impact.

Reduced maintenance costs.

2. Pressure Swing Adsorption (PSA)

PSA technology utilizes selective adsorbents to remove CO2, H2S, and moisture from biogas. This method is highly effective for achieving high-purity methane suitable for vehicular fuel or grid injection.

Advantages:

High purity levels.

Flexibility for varying gas compositions.

Long operational life.

3. Biological Desulfurization

This eco-friendly method uses microorganisms to convert hydrogen sulfide into elemental sulfur. The process is cost-effective and aligns with Kerala’s focus on sustainable practices.

Key Features:

Reduced chemical usage.

Low operational costs.

Sustainable byproduct management.

Success Stories in Kerala’s Biogas Sector

Several biogas plants in Kerala have adopted innovative purification technologies to maximize efficiency and sustainability. For instance:

Community Biogas Projects: Small-scale plants in rural areas are employing membrane separation to produce cooking gas for households.

Industrial Applications: Larger facilities are utilizing PSA systems to fuel machinery or inject purified biogas into local energy grids.

Government Initiatives and Support

The Kerala government has been instrumental in promoting biogas adoption through subsidies, training programs, and awareness campaigns. Initiatives such as the “Waste to Energy” project aim to integrate advanced purification technologies into existing biogas plants, ensuring higher efficiency and broader utilization.

The Road Ahead: Scaling Innovation

For Kerala to fully harness the potential of biogas, continuous innovation in purification technology is essential. Collaborative efforts between government bodies, research institutions, and private enterprises can drive advancements, making sustainable energy accessible to all.

Conclusion

Biogas in Kerala represents a beacon of hope in the quest for renewable energy. By embracing cutting-edge gas purification techniques, the state can transform its biogas sector into a model of sustainability and efficiency. Whether for household use or industrial applications, purified biogas holds the key to a cleaner, greener future.

#biogas in kerala#biogas plant for home#incinerator manufacturers in kerala#biogas#kerala#portable biogas plant for home#incinerators in kerala

0 notes

Text

Honeywell Gas Detector Dealer in hyderabad

Honeywell Gas Detector Dealer in Hyderabad

Honeywell Gas Detection System consists of Fixed and Portable Gas Detectors, Gas Monitors with Alarm System, Gas Analyzers & Wireless Gas Detectors. Our range of Gas Detection Systems cater to various applications and process in every industrial sectors and are widely used in manufacturing plants, power generation / thermal plants, research laboratories, commercial premises, storage or warehouse areas, Underground Car Parking areas, LPG Bullet Yards, Confined Spaces, Battery Rooms & Data centres. Global Naarvi Group is the best Honeywell Gas Detector Dealer in Hyderabad provide best quality products and services to the clients.

Automation is gradually becoming more conspicuous in oil and gas - here we gather the opinions of various industry professionals to evaluate whether that's a good thing or not. LPG Bullet Tank, Vaporizer, We integrate Fire safety integration, Gas Detection System for CNG station.

Global Naarvi Group is the best Honeywell Gas Detector Dealer in Hyderabad provide best quality products and services to the clients.

0 notes

Text

Liquid Off-Take (LOT) Valves for LPG

In industries that rely on liquefied petroleum gas (LPG), efficiency and safety are paramount. Whether it's for heating, transportation, or industrial processes, businesses require reliable and secure ways to handle LPG. One of the most essential components for high-demand LPG applications is the Liquid Off-Take (LOT) Valve. At Prabha Electronics, we offer top-tier LOT valves that are specifically designed to meet these critical needs.

What is a Liquid Off-Take (LOT) Valve?

A Liquid Off-Take (LOT) valve is a specialized valve designed to directly withdraw liquid LPG from cylinders. Unlike vapor off-take valves, which release gaseous LPG, LOT valves enable the extraction of liquid LPG for various applications. This is crucial for processes that require a steady and high-volume supply of liquid gas, such as:

Bulk transportation of LPG

Industrial heating systems

LPG-powered machinery

Large-scale commercial operations

Key Features of the LOT Valve

Our LOT valve is engineered to meet the highest standards of performance and safety. Here are some key features that make it stand out:

Durability and Longevity Made from high-quality, corrosion-resistant materials, the LOT valve is built to last in harsh industrial environments. Its robust construction ensures a long service life, reducing the need for frequent replacements.

Enhanced Safety Safety is always a top priority when handling LPG. The LOT valve is equipped with built-in safety features to prevent leaks and ensure smooth operation. Its precise control mechanisms allow operators to manage LPG flow safely and efficiently.

High-Performance Flow Control The LOT valve provides consistent and controlled liquid LPG withdrawal, which is essential for operations that depend on a steady supply. This makes it ideal for bulk LPG transfer and large-scale industrial applications.

Easy Installation and Maintenance Designed with user convenience in mind, the LOT valve is simple to install and maintain. Its intuitive design ensures smooth integration into existing LPG systems, minimizing downtime.

Applications of LOT Valves

LOT valves play a crucial role in industries that require liquid LPG for energy or processes. Some of the most common applications include:

Industrial Manufacturing: Many industries use liquid LPG for high-temperature heating, cutting, and other processes that require consistent fuel supply.

Bulk LPG Transportation: LOT valves are essential for the transfer of liquid LPG in tanker trucks and other transport systems.

Commercial Cooking and Heating: Large hotels, restaurants, and other establishments that rely on LPG for heating or cooking benefit from the efficiency of LOT valves.

Why Choose Prabha Electronics' LOT Valve?

At Prabha Electronics, we are committed to delivering top-quality products that ensure both efficiency and safety. Our LOT valve is designed to meet the needs of high-demand LPG applications while offering superior durability and control. By choosing our products, you can ensure that your LPG systems are running smoothly and safely.

Conclusion

The Liquid Off-Take (LOT) Valve for LPG is a critical component in industrial and commercial systems that require the use of liquid LPG. Its advanced features, including durability, safety, and performance, make it an essential part of efficient LPG handling. Explore the full potential of your LPG systems with Prabha Electronics' LOT valve and experience a new level of reliability and control.

#Liquid Off-Take Valve#LOT Valve#LPG Valve#industrial LPG valve#liquid LPG extraction#LPG cylinder valve

0 notes

Text

Anil engineering. best lpg vaporizer manufacturer in India.

0 notes

Text

LPG Vaporizer Manufacturers: Top Suppliers & Solutions

Explore high-quality LPG safety fittings and safety valves for secure and efficient LPG systems. Ensure compliance with industry standards for maximum protection and reliability.

#"LPG Storage tanks#Cryogenic Tanks#lpg vaporizer#excess flow check valve#dry electric vaporizers#lpg vaporizer manufacturers#lpg safety valv

0 notes

Text

Top LPG Companies in UAE: Reliable Solutions at Best Prices

Explore top LPG companies in India and UAE. Find reliable and trusted suppliers for LPG solutions. Quality service and competitive prices for your energy needs. Anil Engineering specializes in durable LPG storage tanks and advanced cryogenic tanks, ensuring safety and efficiency for all industrial needs

#LPG Storage tanks#Cryogenic Tanks#lpg vaporizer#excess flow check valve#dry electric vaporizers#lpg vaporizer manufacturers#lpg safety valv

0 notes

Text

iPaaS Market Size, Share, Forecast [2032]

iPaaS Market provides in-depth analysis of the market state of iPaaS manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of iPaaS in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of iPaaS Market Report:

The report offers a comprehensive and broad perspective on the global iPaaS Market.

The market statistics represented in different iPaaS segments offers complete industry picture.

Market growth drivers, challenges affecting the development of iPaaS are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of iPaaS.

Major stakeholders, key companies iPaaS, investment feasibility and new market entrants study is offered.

Development scope of iPaaS in each market segment is covered in this report. The macro and micro-economic factors affecting the iPaaS Market

Advancement is elaborated in this report. The upstream and downstream components of iPaaS and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/ipaas-market-100579

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Alkenyl Succinic Anhydride (ASA) MarketMarket Size

Global Nonprofit Software MarketMarket Share

Global Neonatal Infants Enteral Feeding Devices MarketMarket Growth

Dermatology Drug MarketMarket

Intragastric Balloons MarketMarket Share

Grain Combine Harvester MarketMarket Growth Rate

Requirements Management Tools MarketMarket Forecast

Global Vitamin D MarketMarket Size

Super Capacitor MarketMarket Growth

Nanoemulsion MarketMarket Analysis

EV Charging Cables MarketMarket Size

Global Molecular Diagnostics(MDx) MarketMarket Share

Global LPG Vaporizer MarketMarket Growth

Small Satellite MarketMarket

App Store Optimization (ASO) Tools MarketMarket Share

Commercial Aircraft Autopilot System MarketMarket Growth Rate

Gunshot Detection Systems MarketMarket Forecast

Global Drone Sensor MarketMarket Size

Solar Street Lights MarketMarket Growth

Vacuum Insulation Panels MarketMarket Analysis

In-Vehicle Payment Systems MarketMarket Size

Global Artificial Cornea and Corneal Implant MarketMarket Share

Global Lithium-Sulfur Battery MarketMarket Growth

High Voltage Gas Insulated Switchgear (GIS) MarketMarket

Sodium Hydrogen Sulfide (NaHS) MarketMarket Share

Cloud-based Database MarketMarket Growth Rate

Smart Thermostats MarketMarket Forecast

Global Removable Partial Denture MarketMarket Size

Fiber Optic Connectors MarketMarket Growth

1,2,3,4-Butanetetracarboxylic Acid MarketMarket Analysis

GPS Anti-Jamming System MarketMarket Size

Global Fabric Inspection Machines MarketMarket Share

Global Language Learning Games MarketMarket Growth

Laboratory Freezers MarketMarket

Catheter Holder Market Market Share

Low Thermal Expansion Coefficient PI Films MarketMarket Growth Rate

Dinotefuran Preparation MarketMarket Forecast

Global Kegel Exercise Device MarketMarket Size

Silicon MEMS Printhead Market Market Growth

Redundant Power Supply Units Market Market Analysis

0 notes

Text

Electric Heated Water Bath Vaporizer

Electric heated vaporizer uses special high efficiency electric heater to heat the water inside the cylinder, reheat the low temperature liquid (LOX, LIN, LAR, LCO2, LNG, LC2H4, LPG) in the compact heat exchange tube, adopts the advanced water temperature control system, the gasification amount is extremely stable when working, the outlet temperature is normal temperature or can be set according to the user's requirements. Its main characteristics are as follows.

Company Name:Huzhou Baihui Cryogenic Equipment Co., Ltd Web:https://www.brightwaycryogenic.com/products/water-bath-vaporizer/Water-bath-vaporizer.html ADD:Building A38, China Energy Conservation and Environmental Protection Industrial Park, No. 1506, Yishan Road, Wuxing District, Huzhou City, Zhejiang Province, China Phone:86-18257285710 Email:[email protected] Tip:313000 Profile:Our company is willing to "integrity, innovation, pragmatic, win-win" spirit of enterprise, adhering to create value for users, reduce operating costs of development philosophy! We will wholeheartedly provide new and old customers with high-quality and low-cost products and considerate services, and join hands with our customers to create a better future.

0 notes

Text

Diving into Liquified Petroleum Gas (LPG): Safety, Regulations, Manufacturing Techniques, and Uses

Have you ever used a barbecue or cooked outdoors with a propane stove? If so, you've likely experienced the convenience and flexibility of Liquefied Petroleum Gas, or LPG. This convenient fuel packs a powerful punch, but what exactly is it? In this article, we'll delve into the world of LPG, examining its composition, production process, and its various applications in our lives. We'll also cover safety measures and address some common questions about this widely-used fuel option. Whether you're an experienced grill chef or simply interested in alternative energy sources, stick around for an in-depth look at LPG!

Introduction

Liquefied petroleum gas (LPG), also known as propane, is a flammable mixture of hydrocarbon gases like propane, butane, and others. It's produced during oil refining or extracted from natural gas wells. Made up of various hydrocarbons like butane and propane, LPG is a flammable gas obtained during oil and gas processing. Commonly stored in pressurized cylinders for homes, this versatile fuel also travels through pipelines for large-scale use. A major benefit of LPG is its clean burning nature. Unlike many fuels, LPG is sulfur-free, resulting in fewer emissions. This eco-friendly characteristic makes it popular in households for cooking and heating, as well as in industries for tasks like steam generation and raw material production. You'll also find LPG in common items like aerosols, barbecue grills, and portable heaters.

What makes LPG special is:

Convenient and Clean: Stored in pressurized cylinders for homes (think BBQ tanks!), LPG is a clean-burning fuel with minimal sulfur emissions, making it more eco-friendly than some alternatives.

Versatile Fuel: This gas powers a surprising range of things, from home cooktops and heaters to industrial processes like steam generation. Don't forget those fun summer barbecues!

Transportation: LPG can also be transported efficiently through pipelines for large-scale applications.

Raw Material: Beyond fuel, LPG serves as a key ingredient for producing ethylene, a building block for many plastics.

Aerosol Power: Even some spray cans get their propellant boost from LPG!

Manufacturing Processes

LPG primarily originates from two sources. Approximately 60% of it is derived from the extraction of natural gas and oil deposits from the earth, while the remaining 40% is generated through the refining of crude oil. Historically, LPG was disregarded and burned off as an undesired by-product during the production of other fuel sources. However, it is now acknowledged as a versatile, low-carbon fuel capable of delivering a significant amount of energy.

Natural gas processing initiates at the wellhead, where raw natural gas is extracted from producing wells. The composition of this raw natural gas is contingent upon various factors, including the type, depth, and location of underground deposits, as well as the geological characteristics of the area.

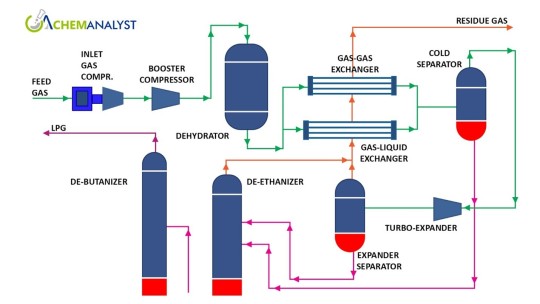

The conventional LPG extraction process involves the utilization of four columns. The initial step in extracting LPG from Natural Gas Liquids (NGL) is the DeEthanizer column. Within this column, methane and ethane are separated, with both components exiting the top of the column. Since there's no need to liquefy methane and ethane, particularly in small quantities, they remain in vapor phase, eliminating the necessity for an additional condenser.

The top product from the DeEthanizer, containing methane and ethane, serves as internal fuel for generating steam used in the column's reboiler. Heat is supplied to the column via forced circulation using a reboiler pump, ensuring efficient operation. Heavier hydrocarbons, excluding ethane, exit the column as a liquid bottom product, subsequently flowing into the DeButanizer column.

The DeButanizer column is chosen over the DePropanizer due to the composition of the bottom product from the DeEthanizer, containing small amounts of propane (2% of mass fraction) and butane (5% of mass fraction). Using smaller columns for subsequent extraction enhances economic efficiency and separation efficacy, requiring less duty for the reboiler.

Before entering the DeButanizer column, the bottom product from the DeEthanizer is depressurized from 26 to 17 bar and introduced into the DeButanizer as mixed-phase feed. Within the DeButanizer, this feed is fractionated into mixed propane and butane as overhead product and heavier hydrocarbons (C5+) as bottom product. The overhead product is fully condensed in the condenser through heat exchange with cooling water, with the resulting condensate collected in a reflux drum to prevent pump cavitation due to vapor phase.

The DePropanizer column separates propane as overhead product and butane as bottom product. The condensed overhead vapor is collected in the reflux drum, with a portion returned to the column as reflux via pump, and the remainder withdrawn as liquid propane product. Reboiler heat in the DePropanizer is supplied by a reboiler, aided by a reboiler circulation pump.

Nearly 100% propane and 99% butane can be recovered from the feed as overhead column product. The butane product, classified as field grade butane, is composed of 30% isobutane and 65% normal butane. This is further processed in a butane splitter to separate isobutane and normal butane.

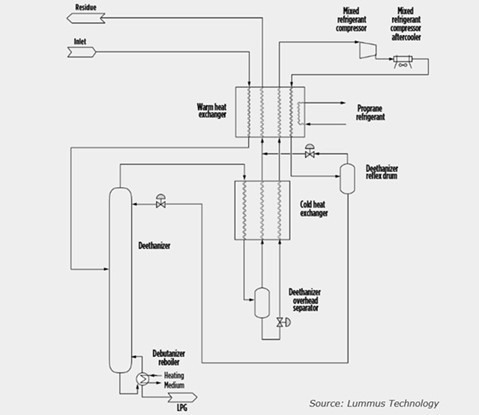

LUMMUS Technologies, one of the leading technology providers of LPG based in US, provides the IPOR (Iso-Pressure Open Refrigeration) Process for the manufacturing of LPG.

This process begins by cooling and partially condensing dry feed gas using a warm heat exchanger, where it interacts with cold process streams, propane refrigerant, and mixed refrigerant. The partially condensed feed gas then goes to the deethanizer for separating the bottom LPG liquid product. The deethanizer reboiler supplies the necessary heat for separation, while the cold reflux stream comes from the open-loop mixed refrigerant (MR) system.

The gas stream from the deethanizer overhead undergoes cooling and partial condensation in the cold heat exchanger. Then, it moves to the deethanizer overhead separator, where the separated liquid acts as the refrigerant for the open-loop MR cycle. The vapor left is residue gas, which gets heated in both the cold and warm heat exchangers.

After the deethanizer overhead separator, the MR liquid's pressure decreases, creating the lowest process temperature. This cold temperature partially condenses the overhead gas stream. Next, the MR stream is heated and vaporized through the cold and warm heat exchangers before going to the MR compressor. The compressed MR stream undergoes cooling and partial condensation again in the warm heat exchanger. The two-phase stream then goes to the deethanizer reflux drum, where the liquid part is used as reflux for the deethanizer column, thus completing the open loop of the MR cycle.

Any non-condensable vapors, mainly methane, along with the vapor from the deethanizer overhead separator, leave the process as part of the residue gas stream. For refinery off gas applications, a hydrogen purification plate-fin exchanger and a hydrogen separator are added after the warm heat exchanger to produce a hydrogen-rich product stream.

The following figure demonstrates the LPG production process:

Major Applications of Liquified Petroleum Gas (LPG)

Domestic

LPG is widely embraced for cooking in homes, with gas cooktops, ovens, and outdoor BBQs being popular choices. The allure of cooking with gas lies in its precise heat control, favored by both amateur cooks and seasoned chefs alike. Gas appliances offer instant adjustments, facilitating seamless transitions between cooking intensities. Furthermore, gas ovens stand out for their ability to maintain optimal moisture levels in food, preserving its succulence and natural flavors.

Commercial

Restaurants and other commercial hubs commonly rely on large industrial-sized gas cylinders. These cylinders ensure a steady and ample supply of gas for the high-volume demands of commercial kitchens and hospitality settings. By utilizing such industrial-scale equipment, establishments can efficiently manage their cooking operations and maintain optimal heating conditions, ensuring the comfort and satisfaction of their patrons. These gas cylinders play a vital role in supporting the smooth functioning of large-scale culinary and hospitality endeavors.

Heating

LPG serves as a versatile heating solution for both residential homes and commercial buildings. Its adaptability allows it to power an array of heating appliances, including space heaters, boilers, and fireplaces. This flexibility makes LPG an attractive choice for various heating needs, providing efficient warmth and comfort while offering the convenience of easy installation and operation. Whether it's warming a cozy living room or maintaining a comfortable temperature in a large office space, LPG stands as a reliable and versatile fuel option for heating application.

Fuel

LPG serves as a cleaner-burning alternative fuel suitable for powering cars, trucks, and buses. Its eco-friendly nature stems from emitting fewer pollutants compared to traditional gasoline or diesel, making it a greener choice for transportation. Beyond its environmental benefits, LPG also presents a cost-effective option, offering potential savings for vehicle owners and operators. By opting for LPG, drivers can enjoy reduced emissions while potentially cutting down on fuel expenses, contributing to both environmental sustainability and economic efficiency in the transportation sector.

Safety Regulations for LPG

LPG is a convenient and reliable fuel, but for the sake of safety it's important to handle and store it responsibly. Here's how to keep yourself and your surroundings safe:

Store it Right: Keep your LPG tanks in a well-ventilated space that's approved for such storage. This means away from anything that could spark a fire, like open flames, heaters, or even direct sunlight. Good airflow helps prevent gas buildup.

Handle with Care: When moving LPG cylinders, use proper lifting techniques to avoid hurting yourself. Always keep them upright and secure them to prevent them from falling over.

Be Leak-Wary: Regularly check for leaks in your tanks, pipes, and appliances. If you find one, clear the area immediately and don't use the LPG until the leak is fixed.

Plan for Emergencies: Have fire extinguishers readily available in LPG storage and usage areas.

Market Outlook

The LPG market is primarily propelled by its high caloric value, making it an efficient energy source for heating and cooking applications, often substituting for natural gas. Its clean-burning properties, characterized by minimal sulfur content, contribute to reduced emissions, driving demand, particularly in regions with strict environmental regulations. With approximately half of its usage allocated to heating and cooking, and the remainder split between automotive and industrial sectors, LPG showcases versatility across diverse applications. Its convenience of delivery, typically via trucks and storage in large tanks, ensures reliable access for residential and commercial users, while portable solutions like reusable gas canisters cater to on-the-go needs, further solidifying its market presence as a significant alternative to traditional fuels.

Liquified Petroleum Gas (LPG) Main Players

Significant players in the Global Liquified Petroleum Gas (LPG) market are IRPC Refinery, ExxonMobil, Indian Oil Corporation Limited, Saudi Aramco, JXTG Nippon Oil & Energy, GASCO, Reliance Petroleum Limited, Bharat Petroleum Corporation Limited, and Others.

Liquified Petroleum Gas (LPG) Market Challenges

The LPG industry market is also facing a few bumps. Here's a breakdown of the key hurdles:

Price Rollercoaster: LPG prices are like a thrill ride, prone to sharp swings due to factors like crude oil costs, political tensions, and imbalances between supply and demand. This volatility makes budgeting and planning an issue for both consumers and suppliers.

Supply Chain Snags: Disruptions in the supply chain, caused by natural disasters, political conflicts, or infrastructure breakdowns, can throw a wrench into getting LPG where it needs to go. Ensuring a smooth-running and reliable supply chain is vital to meeting market needs.

Alternative Energy on the Rise: LPG is facing growing competition from alternative energy sources like natural gas, electricity, and renewables. As consumer preferences shift, governments offer incentives, and technological advances for these alternatives, the demand for LPG could take a hit.

Conclusion:

Liquefied Petroleum Gas, or LPG, is a versatile fuel option gaining traffic due to its amazing properties. This flammable mixture, extracted from oil and gas wells, is primarily composed of carbon-based compounds like butane and propane. Stored in pressurized cylinders for household use, LPG can also be transported through pipelines for large-scale applications. One of LPG's biggest advantages is its clean burning nature. Unlike traditional fuels, LPG is virtually sulfur-free, resulting in significantly fewer emissions. This characteristic makes it an attractive alternative for both domestic and transportation sectors, driving the predicted growth of the LPG market. Furthermore, LPG's clean combustion paves the way for its potential substitution of more polluting fuels in the near future. With its eco-friendly profile and efficient burning properties, LPG is well-positioned to become a fuel of choice in the years to come.

0 notes